Positive Displacement Flow Meters

VAF Mid-Flow Sliding Vane...

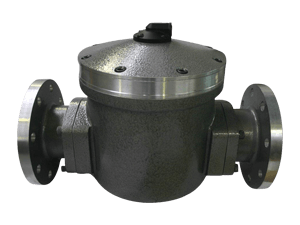

D/Iron and S/Steel 1" to 4" Flow Meters

VAF Mid-Flow Sliding Vane...

D/Iron and S/Steel 1" to 4" Flow Meters

VAF ProFlow Sliding Vane

Positive Displacement Flow Meter 1/2" - 2"

VAF ProFlow Sliding Vane

Positive Displacement Flow Meter 1/2" - 2"

VAF LoFlow Series J

Vane Meter in Steel and Stainless Steel

VAF LoFlow Series J

Vane Meter in Steel and Stainless Steel

VAF Hi-Flow Sliding Vane

Positive Displacement Flow Meter 150mm-300mm

VAF Hi-Flow Sliding Vane

Positive Displacement Flow Meter 150mm-300mm

LoFlow/MidFlow Model PT

Fuel Oil Sliding Vane Meters DN 15-50 (1/2"-2")

LoFlow/MidFlow Model PT

Fuel Oil Sliding Vane Meters DN 15-50 (1/2"-2")

Micropulse Gear

Positive Displacement Flow Meters

Micropulse Gear

Positive Displacement Flow Meters

Multipulse Gear

Positive Displacement Flow Meter

Multipulse Gear

Positive Displacement Flow Meter

Trigear Flow Meters

Positive Displacement Flow Meter

Trigear Flow Meters

Positive Displacement Flow Meter

OM Large Capacity Oval Ge...

Oval Gear Flow Meters

OM Large Capacity Oval Ge...

Oval Gear Flow Meters

Positive Displacement Flow Meters

Overview

A positive displacement flow meter, or 'PD Meter,' measures flow through a closed pipe. It works by displacing a precise volume for each revolution of its internal parts. Types of internals include oval gear, nutating disc, rotary piston, and sliding vane. This style of flow meter displaces a known volume, so its accuracy is unaffected by changes in liquid properties like viscosity or density. A ‘litre’ is always a ‘litre’ regardless of viscosity or density. Therefore, a PD flowmeter is extremely accurate, with linearity better than 0.1% of reading and repeatability better than 0.05%.

Accuracy

To ensure high accuracy, the clearances inside the measuring chamber must be fine without causing excessive wear. Thus, the liquids must be clean and free from suspended solids. Installing a suitable liquid filter on the inlet side of the meter is prudent. Positive Displacement flow meters require no upstream/downstream straight pipe lengths, so a filter can be directly bolted to the inlet port.

A small amount of liquid will pass through the flowmeter without passing through the measuring chamber. This occurs between the rotor and the side plates of the meter. Although this ‘slippage’ is small, it is essential to calibrate each flow meter before dispatch. Flow meters are generally calibrated using a low viscosity liquid where slippage is highest. As viscosity increases, slippage reduces because it is harder for thicker liquid to pass by the sides of the rotor.

The flow range of PD meters is often dictated by the working viscosity. Manufacturers usually quote flow ranges at 1cP viscosity. As working viscosity increases, so does the pressure drop through the flow meter. If pressure drop reaches one bar and flow rate is below that stated for 1cP, this flow rate is the maximum flow allowed under these conditions. On the plus side, as viscosity increases, so does the minimum flow available to measure due to reduced slippage.

Uses

Positive Displacement flow meters have been used in truck delivery of fuel and chemicals for many years. Mechanical accessories can be fitted to the flowmeter to provide a highly accurate measuring system. Accessories include liquid strainer, air eliminator, batch pre-set register, large numeral reset totaliser, zero-start or accumulative ticket printer, flow non-return valve, and mechanical batching valve. Where an electronic output is required, the flowmeter can be fitted with a pulse transmitter to input to remote instrumentation. Pulse Transmitters are available with ATEX Approval where necessary. Exd Pump Switches can be fitted inside the LNC or a Pneumatic Switch Box to switch the air supply for pneumatic batch systems.

Applications

Positive Displacement flowmeters are ideal for applications requiring customer billing. Many flowmeters carry Weights & Measures / MID Approval, and flowmeter registers are often lead-sealed to prevent tampering.

PD meters also measure very small flows down to less than one litre per hour. They are the flowmeter of choice for many oil and pharmaceutical companies where high accuracy is essential. Fuel oil additive metering and additive injection are typical applications where reliable mechanical metering solutions are required.

A positive displacement flow meter offers such high accuracy that many flow testing and calibration facilities install them as reference meters. These reference flowmeters are usually calibrated by a National Standards Authority so testing houses can claim accuracy traceable to National Standards such as UKAS.

Our Positive Displacement Meters

Flowquip offers positive displacement flowmeters manufactured by VAF Instruments. VAF has been manufacturing flowmeters for seventy years and is one of Europe’s leading flow specialists. Our range of VAF PD meters includes:

- LoFlow Vane meters handle flows from 1 to 50 l/min, ideal for continuous flow measurement and batching applications.

- MidFlow Vane meters handle flows from 5 to 2750 l/min, ideal for metering hydrocarbons and chemicals. MidFlow Vane meters are available with various register and pulse transmitter options.

- HiFlow Vane meters handle flows from 230 to 16000 l/min, ideal for larger continuous flow measurement or batching applications.

All VAF flowmeters have ATEX Approval, and LoFlow, MidFlow, and HiFlow flowmeters can be supplied with MID (Custody Transfer) Approval.

For more information, call us on 01422 829920 or email sales@flowquip.co.uk.

Should you wish to hire a flow meter, this can be done through our sister company Flowhire Ltd.